willisbr

Active Member

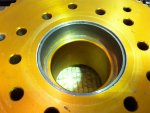

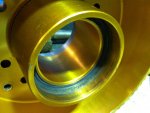

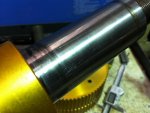

I have some back and forth play in the prop that i originally thought was a worn jackshaft. After closer look at the belt sprocket, it seems that the sprocket may be faulty. The bearing on the mounting plate side can be pushed in and out by hand. Wasn't like this before. I pressed it out last time when I changed the bearings but now that one is very lose. Wiggles in place. On one bearing side, the inside is still anodized and the bearing requires a press to set but on the problem side it looks and feels lathed. It's shiny and smooth with a lip at that the top. Please watch video to see. What are your thoughts? *Is this normal? *If not how could this have happened? *What can I do to fix? *Possible to hone and fit a new bearing? *Thanks

Always great to find such an issue so close to Bensen Days.

Check out this video on YouTube:

YouTube - RAF 2000 Drive Sprocket

Always great to find such an issue so close to Bensen Days.

Check out this video on YouTube:

YouTube - RAF 2000 Drive Sprocket