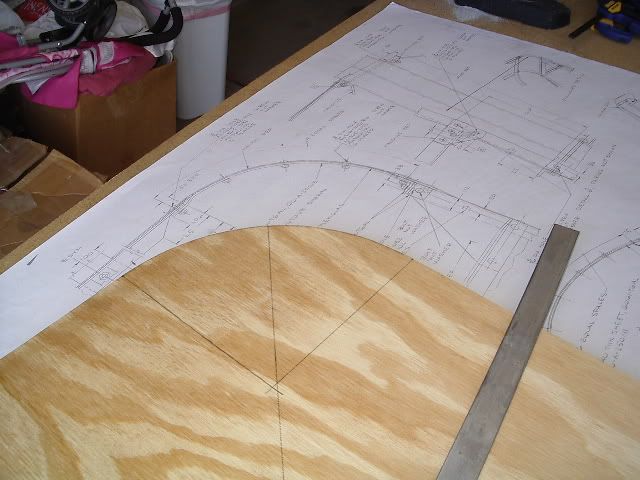

As you can see, the cabin enclosure is starting to come together.

Yes, now it’s looking like a real HA-2M Hamster

Palm Pilot, I like your signature line… I combined Cyclic and Joystick… I call my control mechanism a cycostick. It’s pronounced as psycho-stick…

Sorry Scott, I was not in the C-130 world until just after 9-11 and only went to POPE to throw men out the back of my airplane. You know when I was a kid my dad would back-hand in the seat for tossing trash out the window of the car as we whizzed down the interstate… Then when I joined the USAF C-130 world, the government paid me to toss stuff out the back of a moving airplane.

I gotta tell you this story real quick. The C-130 and the maintenance man are like a marriage. The mechanic lovingly cares for her, and puts so much time an effort into keeping her in tip-top shape. He is dedicated to her, and spends countless hours with her getting her just right. She is beautiful and he is dedicated and faithful.

Then, at sun down, we aircrew boys show up, swipe the logbook, check her out real close, and we really like what we see… man is she smooth! We stuff her so full of cargo, she wants to bust open at the seams. We take her for a ride, a looooong ride. We bang, jostle and pound the holly hell out of her all night long. We make her perform like she was made to perform, and push her right to her limits, actually a little over her limits… to the point we break something down there on her insides. She limps back home with us, and we dump her hot tired broken chassis on the driveway. We give each other high-5’s, and laugh and go huah huah huah, and chest bumps as we re-live last nights grand adventures. We point out ALL of her flaws to the poor maintenance man.

As we walk away, I look over my shoulder, and I think I see a tear drop on his cheek in the morning sun light. Oh never mind him, look at my C-130, she is gorgeous, really hot! I blow her a kiss, and I whisper a thank you to her, and tell her how much fun I had last night. See you again tomorrow night my love I say… The mechanic takes a few hours to forgive her; but then, once again he begins his nurturing and loving, cleaning her up, and fixing her wounds and bruises. He really really cares for her… but I’ll be back tomorrow night, and she will leave him once again to party all night long with the boys.

This is why USAF mechanics hate pilots and aircrew… He really loves his C-130, and can’t understand why she always seems to stray… The C-130 is a really bad girl, and us aircrew boys know it