Foamandtape

Newbie

Hi all,

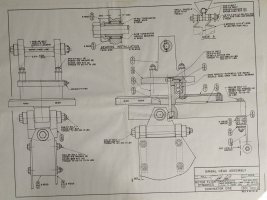

First post but have recently acquired a nicely built bee and am just going through it and replacing any thing questionable or just upgrading bolts to AN drilled with castellated hardware for any supercritical components but have noticed the only non AN hardware on the machine is on the rotor head and its associated bolts?? After doing some digging I found this was a factory thing and am quite shocked that using JH grade 8 hardware is the stock stuff it came with. I have replaced the teeterbolt with the appropriate AN bolt since I can add a castellated nut and cotter pin it, the same was done for the pitch and roll blocks. I dont have any documentation on the bolts that hold the bearing to the block and don't want to disassemble it further as I don't have any experience with the rotor head. Seems sort of trivial to save a few bucks on hardware especially for something as critical as the rotor!

Thoughts?

thanks again!

First post but have recently acquired a nicely built bee and am just going through it and replacing any thing questionable or just upgrading bolts to AN drilled with castellated hardware for any supercritical components but have noticed the only non AN hardware on the machine is on the rotor head and its associated bolts?? After doing some digging I found this was a factory thing and am quite shocked that using JH grade 8 hardware is the stock stuff it came with. I have replaced the teeterbolt with the appropriate AN bolt since I can add a castellated nut and cotter pin it, the same was done for the pitch and roll blocks. I dont have any documentation on the bolts that hold the bearing to the block and don't want to disassemble it further as I don't have any experience with the rotor head. Seems sort of trivial to save a few bucks on hardware especially for something as critical as the rotor!

Thoughts?

thanks again!