GyroRon

Former Gyro know it all

- Joined

- Oct 29, 2003

- Messages

- 16,891

- Location

- Fort Mill South Carolina

- Aircraft

- Vans RV4 / Dominator 582 Ultrawhite

- Total Flight Time

- ALOT

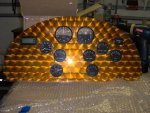

Mr Negative checking in....... I hope it doesn't cast too much glare, the shine of the orange might get bothersome if the sun is beating down on it and reflecting it in your eyes, Otherwise it looks pretty cool. Gonna have to nickname your gyro with some kind of pumpkin or halloween theme