You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My Engine

- Thread starter treaze

- Start date

treaze

Newbie

My Engine

Slightly off topic, but here's a pic of an idea for the Hall ASI instl. That's their small indicator that goes to 70 mph and their long brkt. I know the stick will need to be trimmed probably quite a bit after I get the hang test done, but this is it for now.

Slightly off topic, but here's a pic of an idea for the Hall ASI instl. That's their small indicator that goes to 70 mph and their long brkt. I know the stick will need to be trimmed probably quite a bit after I get the hang test done, but this is it for now.

Attachments

Rick Martin

Gold Member

- Joined

- Apr 20, 2004

- Messages

- 2,162

- Location

- BRADENTON, FLORIDA & FL10

- Aircraft

- Everglades Kite Gyro, Tandem Dominator

- Total Flight Time

- 900 hours

I used a Bell bicycle mirror on my Bee. I think I just mounted a piece of the proper diameter tubing somewhere and used that.

I'll do the same thing on the Gator Gyro at some point.

I'll do the same thing on the Gator Gyro at some point.

treaze

Newbie

My Engine

Rick - What dia mirror did you use? The pic here has an X on the main gear vert strut more or less where I think Ralph had his mirror located--was yours anywhere near that? Does anybody have a pic of their installation?

The pic also shows a bit of progress. I finished my tank vent assy using an AN840-4D fitting (tap the Starbee tank vent hole for 7/16"-20NF threads) and an in-tank fuel filter (ACSpruce p/n 05-01031). If I'm correct, it should allow normal airflow both into and out of the tank, but the check valve should shut off loss of fuel in the event of an upset.

I also calibrated the tank, and marked the gallon points with special aviation-grade magic marker (ha ha).

Rick - What dia mirror did you use? The pic here has an X on the main gear vert strut more or less where I think Ralph had his mirror located--was yours anywhere near that? Does anybody have a pic of their installation?

The pic also shows a bit of progress. I finished my tank vent assy using an AN840-4D fitting (tap the Starbee tank vent hole for 7/16"-20NF threads) and an in-tank fuel filter (ACSpruce p/n 05-01031). If I'm correct, it should allow normal airflow both into and out of the tank, but the check valve should shut off loss of fuel in the event of an upset.

I also calibrated the tank, and marked the gallon points with special aviation-grade magic marker (ha ha).

Attachments

Alan_Cheatham

Member

treaze

Newbie

Thanks, Alan - Scaling it off against the strut dia, I estimated it's about a 3-1/2 dia mirror. Would that be pretty close? And it looks to be a flat one, not convex--is that right? Any other details, such as mounting/adj method, that you might share?

treaze

Newbie

My Engine

It wasn't until after I posted last, Alan, that I noticed the mirror pic you posted wasn't of yours. Anyway, after a lot of research, I think I finally found a mirror (4"Dia, flat) that may work after I cut the stalk down to size, and ordered it from Amazon today.

In the meantime, trying to get every possible piddly thing done before biting the bullet and ordering an engine, I made up my dummy cheek plates from 1/2" ply, using Dawg's pattern--thanks again.

Next, if I can persuade LEAF to ever credit back my card for backordered cables I canceled, I'll order the extension cables I need for the senders directly from Westach.

It wasn't until after I posted last, Alan, that I noticed the mirror pic you posted wasn't of yours. Anyway, after a lot of research, I think I finally found a mirror (4"Dia, flat) that may work after I cut the stalk down to size, and ordered it from Amazon today.

In the meantime, trying to get every possible piddly thing done before biting the bullet and ordering an engine, I made up my dummy cheek plates from 1/2" ply, using Dawg's pattern--thanks again.

Next, if I can persuade LEAF to ever credit back my card for backordered cables I canceled, I'll order the extension cables I need for the senders directly from Westach.

Attachments

Dirtydog

Best seat in the house!

- Joined

- Oct 13, 2008

- Messages

- 2,298

- Location

- South, SC

- Aircraft

- Dogbee / Gyrobee

- Total Flight Time

- 18 duel/ 55 hrs in the Dogbee

treaze :

Hey you could have used some thin sheet metal from home depot. You could have taken your time with them.

Do you have the rotor head yet?

Hey you could have used some thin sheet metal from home depot. You could have taken your time with them.

Do you have the rotor head yet?

treaze

Newbie

My Engine

Well, fuel is related to the engine, so the fuel indicating system must also be related to the engine, right?--so I'm posting it here in this thread. This is really more heavy duty than I liked, being made of steel as it is. I hacksawed the stalk much shorter to save weight, and slotted the holes, ground off some threads, and removed the cushioning so that it would fit on the 1" tubing, and replaced the supplied nut and lockwasher with a nylock (from Ace Hardware) and AN washer--it weighs a total of 8.35oz. It's a 4" flat mirror, and seems to work pretty well, although I have to move my head around a bit to make sure which tank markings I'm looking at--I may end up adding numerals.

Dawg - No, I don't have my rotor head yet. Probably either that or the prop are my next major purchases.

Well, fuel is related to the engine, so the fuel indicating system must also be related to the engine, right?--so I'm posting it here in this thread. This is really more heavy duty than I liked, being made of steel as it is. I hacksawed the stalk much shorter to save weight, and slotted the holes, ground off some threads, and removed the cushioning so that it would fit on the 1" tubing, and replaced the supplied nut and lockwasher with a nylock (from Ace Hardware) and AN washer--it weighs a total of 8.35oz. It's a 4" flat mirror, and seems to work pretty well, although I have to move my head around a bit to make sure which tank markings I'm looking at--I may end up adding numerals.

Dawg - No, I don't have my rotor head yet. Probably either that or the prop are my next major purchases.

Attachments

Dirtydog

Best seat in the house!

- Joined

- Oct 13, 2008

- Messages

- 2,298

- Location

- South, SC

- Aircraft

- Dogbee / Gyrobee

- Total Flight Time

- 18 duel/ 55 hrs in the Dogbee

Treaze :

Although I have to move my head around a bit to make sure which tank markings I'm looking at--I may end up adding numerals.

I would go with the numbers just for that reason..... you know at a glance

Although I have to move my head around a bit to make sure which tank markings I'm looking at--I may end up adding numerals.

I would go with the numbers just for that reason..... you know at a glance

Last edited:

treaze

Newbie

My Engine

Yeah, I did go with the numbers--as you can see in the pic. I used Magic Marker with a stencil--I wonder how durable they'll be.

And I got some extension cables ordered from Westach for my quad, and a cable for the tach.

I think my next expenditure will be the prop. And what I've been thinking of is a wood, two-bladed Tennessee 60"x38", for cost and weight, to hang onto my eventual Rotax 447 with B gearbox. But I've seen pitch numbers in the Forum from 34" to 36", too. Any comments or suggestions? I'm approx 140#, in an UL machine, at sea level in Flori-duh.

Yeah, I did go with the numbers--as you can see in the pic. I used Magic Marker with a stencil--I wonder how durable they'll be.

And I got some extension cables ordered from Westach for my quad, and a cable for the tach.

I think my next expenditure will be the prop. And what I've been thinking of is a wood, two-bladed Tennessee 60"x38", for cost and weight, to hang onto my eventual Rotax 447 with B gearbox. But I've seen pitch numbers in the Forum from 34" to 36", too. Any comments or suggestions? I'm approx 140#, in an UL machine, at sea level in Flori-duh.

Attachments

Dirtydog

Best seat in the house!

- Joined

- Oct 13, 2008

- Messages

- 2,298

- Location

- South, SC

- Aircraft

- Dogbee / Gyrobee

- Total Flight Time

- 18 duel/ 55 hrs in the Dogbee

Treaze : Great to see still plugging at it. I have used the same thing to mark mine in the past (Magic Marker ) will stay for a while but not long when the gas gets on it. Warp drive I know is the heavier prop. I don't know any thing on the wooden props.

Are they lighter that a IVO?

I would ask a few of the other guys that have flown the woodies

https://www.rotaryforum.com/forum/forumdisplay.php?f=30

Are they lighter that a IVO?

I would ask a few of the other guys that have flown the woodies

https://www.rotaryforum.com/forum/forumdisplay.php?f=30

treaze

Newbie

Dawg - Thanks for the links. But everybody with potential input re Tennessee prop pitch experience must be on vacation. Frustrating!

I run a 60x36 tennessee on mine and get about 6100rpm static on the ground.

The 60x38 would probally be too big, make sure you use the 2.58-1 b gearbox. :rapture:

The 60x38 would probally be too big, make sure you use the 2.58-1 b gearbox. :rapture:

I think my next expenditure will be the prop. And what I've been thinking of is a wood, two-bladed Tennessee 60"x38", for cost and weight, to hang onto my eventual Rotax 447 with B gearbox. But I've seen pitch numbers in the Forum from 34" to 36", too. Any comments or suggestions? I'm approx 140#, in an UL machine, at sea level in Flori-duh.

treaze

Newbie

My Engine

Thanks Red. I'll try this again--I wiped out my response just a minute ago somehow--aaaauuuugh! Are you happy with the 36" pitch as an all-around performer? I was tending towards that lately anyway, as midway between the pitches I've been seeing--moderation in all things. I have an email into TPI, but it's 'only' been 9 days so far with no response, after all. I was wondering how to specify the flange holes. The 447 instl manual shows two sets of 6 holes each, one set M8 and the other what appears to be 6.015mm. Which is right for us, and why? And what's your hub thickness? Thanks.

Thanks Red. I'll try this again--I wiped out my response just a minute ago somehow--aaaauuuugh! Are you happy with the 36" pitch as an all-around performer? I was tending towards that lately anyway, as midway between the pitches I've been seeing--moderation in all things. I have an email into TPI, but it's 'only' been 9 days so far with no response, after all. I was wondering how to specify the flange holes. The 447 instl manual shows two sets of 6 holes each, one set M8 and the other what appears to be 6.015mm. Which is right for us, and why? And what's your hub thickness? Thanks.

Attachments

treaze

Newbie

My Engine

Several posts ago, I mentioned that I had ordered a Rotax inline fuel filter from Ultralightnews. They never delivered and never responded to my inquiry, so beware of them--I wonder what they did with my cc info. So I ordered two from Lockwood (they have an obnoxious $10 minimum). They are the only company that I am aware of that sells Rotax p/n fuel filters, and I figured that was a safe way to go. What I received were Fram G1 filters with a Rotax 414-3636 p/n sticker on the boxes. So I thought I'd finally find out if these filters met Rotax's own spec for mesh size of 0.15mm. But not--I couldn't find any mesh size spec in Fram's specs. And furthermore, Rotax says don't use paper elements, and that's what these are. And especially oddly, Bing's manual doesn't mention the topic at all. I hate to make a mountain out of a molehill, but sheesh, you'd think info like this would be available and it'd all make sense.

Does anybody have a contact for Rotax factory tech support, if there is such a thing? I've never encountered one.

Several posts ago, I mentioned that I had ordered a Rotax inline fuel filter from Ultralightnews. They never delivered and never responded to my inquiry, so beware of them--I wonder what they did with my cc info. So I ordered two from Lockwood (they have an obnoxious $10 minimum). They are the only company that I am aware of that sells Rotax p/n fuel filters, and I figured that was a safe way to go. What I received were Fram G1 filters with a Rotax 414-3636 p/n sticker on the boxes. So I thought I'd finally find out if these filters met Rotax's own spec for mesh size of 0.15mm. But not--I couldn't find any mesh size spec in Fram's specs. And furthermore, Rotax says don't use paper elements, and that's what these are. And especially oddly, Bing's manual doesn't mention the topic at all. I hate to make a mountain out of a molehill, but sheesh, you'd think info like this would be available and it'd all make sense.

Does anybody have a contact for Rotax factory tech support, if there is such a thing? I've never encountered one.

Attachments

treaze

Newbie

Hey Dawg - The engine's off a bit yet. I want to do the prop and rotor head first. In the meantime, I'm puttering on several little extremely frustrating projects that are driving me crazy. Like, the filter thing that's impossible to get info on, prop info that's so hard to come by, and the tension spring ass'y, the worst of all--that's the subject of my next rant, I think.

the 60x36 seems to be a happy medium. You don't wanna exceed 6500rpm at full power in the air.

I don't remember their being two sets of holes on my gearbox flange but I could be wrong, I used m8 metric bolts since thats what I had on hand from a warp drive prop.

The hub thickness is 1/4"

https://www.aircraftspruce.com/catalog/appages/fuelfilter.php

I don't remember their being two sets of holes on my gearbox flange but I could be wrong, I used m8 metric bolts since thats what I had on hand from a warp drive prop.

The hub thickness is 1/4"

https://www.aircraftspruce.com/catalog/appages/fuelfilter.php

Thanks Red. I'll try this again--I wiped out my response just a minute ago somehow--aaaauuuugh! Are you happy with the 36" pitch as an all-around performer? I was tending towards that lately anyway, as midway between the pitches I've been seeing--moderation in all things. I have an email into TPI, but it's 'only' been 9 days so far with no response, after all. I was wondering how to specify the flange holes. The 447 instl manual shows two sets of 6 holes each, one set M8 and the other what appears to be 6.015mm. Which is right for us, and why? And what's your hub thickness? Thanks.

Attachments

treaze

Newbie

My Engine

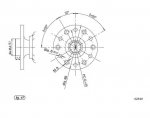

Red - Thanks for info and pics. TPI lists prop hubs of 1.5, 1.75, 2, 2.25, and 3". Which did they give you?? I used my apparently inadequate photo analysis skills on your pic and came up with 2.55", but that can't be right. The pic below shows the multiple sets of flange holes, which jibes with the instl manual dwg I posted in previous post, showing 12 holes. I've seen some pics that show nuts at the rear of the flange, but I've also seen mention that the holes are tapped. Maybe one set is tapped and the other isn't--who the H*** knows? There's no clue in Rotax's inst manual, and no info I can find elsewhere. It's like pulling teeth. But what's new?

Red - Thanks for info and pics. TPI lists prop hubs of 1.5, 1.75, 2, 2.25, and 3". Which did they give you?? I used my apparently inadequate photo analysis skills on your pic and came up with 2.55", but that can't be right. The pic below shows the multiple sets of flange holes, which jibes with the instl manual dwg I posted in previous post, showing 12 holes. I've seen some pics that show nuts at the rear of the flange, but I've also seen mention that the holes are tapped. Maybe one set is tapped and the other isn't--who the H*** knows? There's no clue in Rotax's inst manual, and no info I can find elsewhere. It's like pulling teeth. But what's new?