I also built most of a G1 about 15 years ago just as a tinkering project. A divorce eliminated the project funding, and the ex took it for psych-ops effect.

There are several substantial problems with a G-1 that need worked out. #1 you can’t fly a weight shift helicopter, it just doesn’t really work. Theories are great until a tiny wind poofs you. Also, never fly a fixed pitch helicopter at any altitude higher than you intend to fall, as autorotation is not possible.

To make a G-1 a functional helicopter, you need a full collective rotor head, and full functioning (real) tail rotor. You can adapt those parts from different designs easily enough however.

The engine problem…the G-1 has the crankshaft(s) of the engine(s) mounted in the vertical axis. The original G1 used three 15 HP go-cart engines and never flew. To be honest, I don’t know of any engine manufacturer that authorizes such orientation under normal operating conditions. They can be in that orientation temporarily, such as in a loop-the-loop. The problem is that the weight of the crank shaft should generally not rest constantly on the thrust bushing at what is (now) the lower end of the engine, or it will polish it to oblivion in probably under 50 hours, even with 20:1 oil mix. The thrust bushings on the crankshaft ends of most 2 strokes are not intended to function is this manner for any length of time. I'm talking about snowmobile style engines here generally speaking.

This is not really a problem; you just need to mount the engine like you do in a big chopper with a horizontal crankshaft output. This however requires the use of a clutch, a gear box / 90 Deg angle transmission, and a final step down gear at the rotor head. Again this is not at all a problem…

It may seem funny, but a great 90 Deg angle transmission that is (DIRT) cheap to obtain and (EASY) to mount in a shop built frame is the lower part of the transom of a 75 to 90 HP outboard boat motor.

Of course you have to modify the input and output shafts at a machine shop and use appropriate drive shaft couplings, but the gearing in the transom helps step down engine RPM , which you will need to do anyway.

A second bonus of modifying the lower end of a boat motor transom is that it’s built out of aluminum, so it’s light weight. It’s also rated by HP which it is engineered for, so you know you won’t blow the angle drive under flight load.

If you are concerned that people will be alarmed in seeing a helicopter using an Evinrude boat transom as the right angle gear box, that is also not a problem. It’s easy to make a .040 aluminum cover to hide transmission from view. Most people will never know you are using it, unless they remove the cover plate and inspect.

I fully believe that you can make a G1-A for less than 254 pounds, but it will be close at the end. I truly think you can do it. You will want to aim for a 65HP or 70 HP air cooled engine, as you are turning engine power through a lot more bearing points than just an airplane engine does. You have the clutches assembly, 90Deg trans, tail rotor and associated bearings, and rotor head drive. Use 60 to 70 HP forced air engine like a Hirth or equivalent. You MUST have a force air engine, free air won’t cut it.

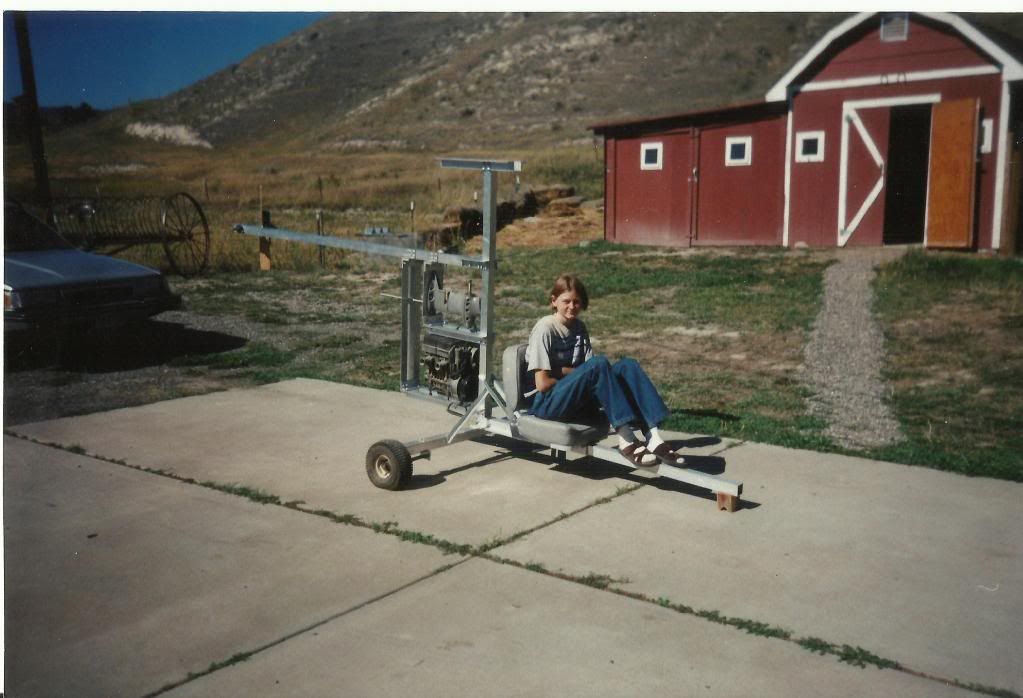

My G-1A had a 503 Fan cooled engine and and a 75 HP Evinrude transom mounted in the frame. The airframe frame was complete, and I was at about 120 Pounds, without the clutch, rotor hubs or blades. I'll dig around and see of I can find any old photos, I have them somewhere.

I know this project can be done, but it will be a challenge.