Mike Jackson said:

I believe I saw a thread on this topic but it may have been in the old forum. Is it acceptable to cut 061 T-6 with a table saw? I think the short answer is yes but there were good techniques. Type of blade? Finer toothed? High speed of rotation? Speed to feed? Clean cuts? Safety considerations?

Hi Mike.

In my experience table saws are excellent for cutting aluminum, both tubing and sheet, unless the angles become exceedingly sharp. I have been getting near-mirror sawn ends with a

Freud 10", 96-tooth carbide tipped blade. I've had it a few years so I'm not up on the specifics. I actually bought it at a woodworking supply company for use in building my wooden Mini-Max FW, and I think I paid around $100 for it. I never anticipated building a Gyro with it but it has since proved its worth.

I'm attaching a couple of pix that show a taste of what a good blade can help you do.

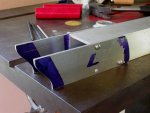

Image 1: Rudder pedal pivot brackets (4) saw-cut on many surfaces. These were table saw-cut from 2 x 2 tubing doing 2 rip-cuts and 5 cross-cuts (the first just to true up the end.) From there a simple hand file does wonders for deburring the edges. Also note the general smoothness of the uppermost ends. You can almost see your reflection in them. The 'milky' areas are how the light was hitting them.

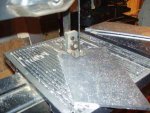

Image 2: Plate Stock can also be cut with relative ease. In most cases you can control the exact cut line based on the geometry of the table bed itself. In the image I clamped an angle to the part which served as a T-Square. If using a movable fence make sure the fence's bottom remains closer to the work surface than your material is thick.

Image 3: Nose block plates are a perfect example of using what limited tools you have to their fullest. Straight edges are table-cut and curved edges are table-assisted. I discovered we could use the table saw as a 'Nibbling' tool to remove material from an inside angle or curve. The trick is to raise your blade height to maximum such that the tooth path is more downward than angled.

Mike, I still have tons to learn so I can only volunteer what I know. But I'm often reminded of the guy that discovered how to calculate longitude with a lot less. The whole point is to show that tools you may already have can be used to good measure in ways they were never inteded.

Have a great evening. Do something fun and unexpected, even if it's free.

Cheers,

Brian Jackson