Now We Are Cookin' With Gas....

Now We Are Cookin' With Gas....

Got to spend another 2 hours in the garage tonight.... it was really satisfying work, as everything happened just as Nicolas shows in his construction videos.

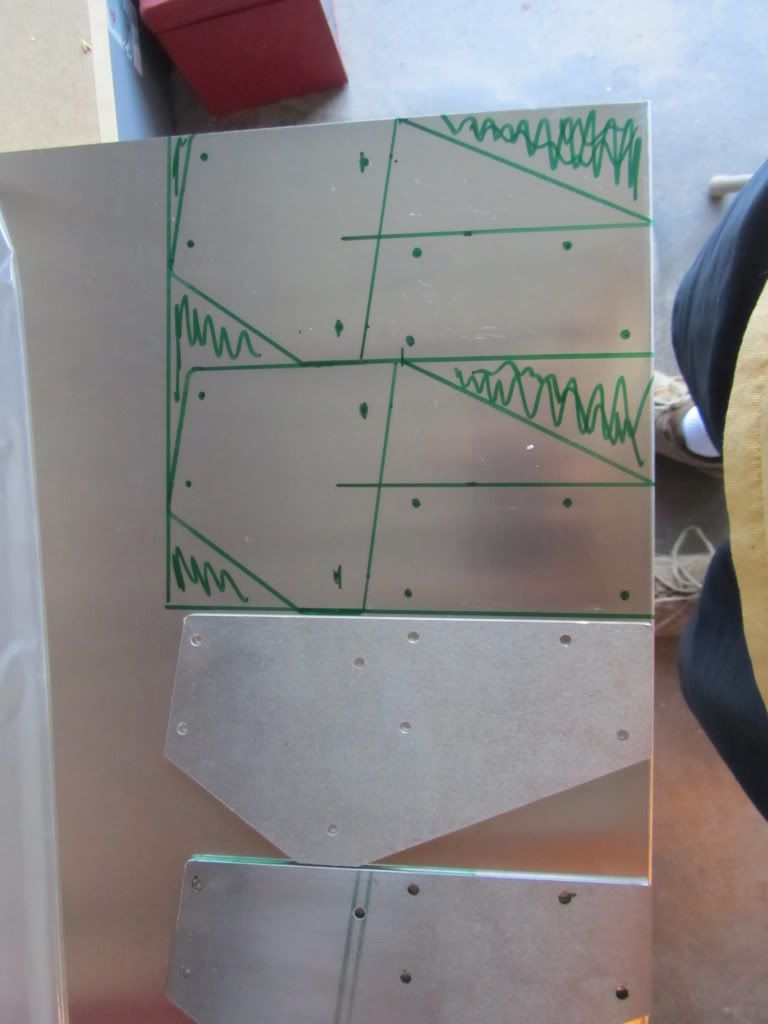

First, I marked and cut the V-cut in the keel, which allows the keel to bend up under the prop. I have to admit to a little "pucker factor" on this cut.... I just knew I was going to let the saw get away from me and ruin this metal that I've waited a long time for....

Here's the cut keel, ready for plates and bending....

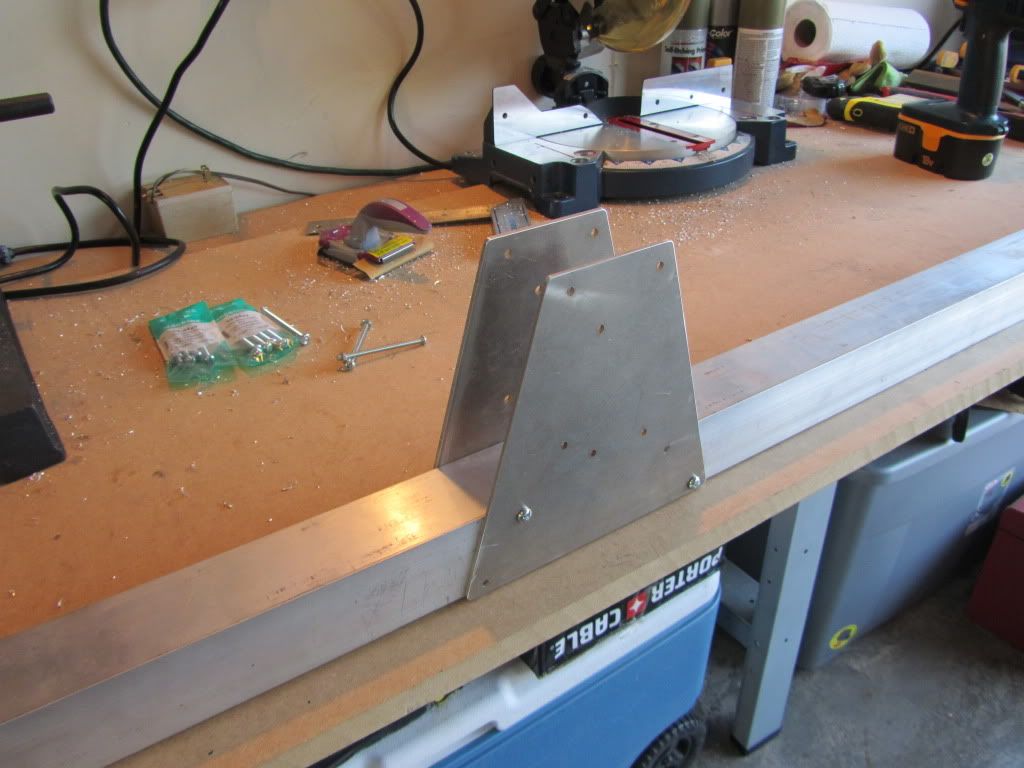

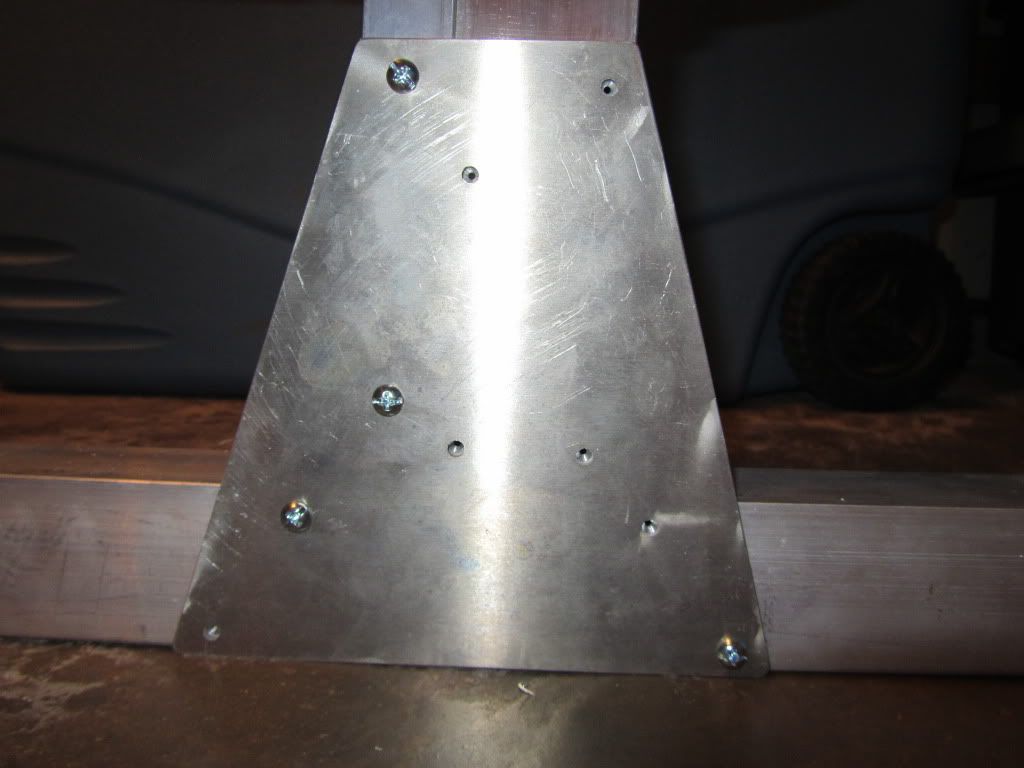

Here's the plates attached and keel bent up.... a very precision fit, thanks to Nicolas' pilot drilled plates and keel.

Next I moved on to the plates for attaching the mast and mast support tubes....

Next I attached the mast support tube...

Then I moved on to building the mast.... the two 1x2 tubes must be bolted together with small bolts on the inside, making sure to keep proper alignment of the tubes...

Here's the bolting method, with one on each end....

And the completed mast on the work bench.....

I then clamped the mast into position on the frame and checked for bolt hole alignement....

Perfect alignment of all plate holes and pilot holes in the mast.... So far, everything has lined up perfectly, with no issues at all. I'm very pleased with the kit so far...

On Saturday I will actually attach the mast and move forward with the rest of the frame..... no work for me on Friday, as we have friends throwing a high school graduation party for their daughter.