Vance,

This is an area where you probably are one of the most experienced people on here. Your work with going fast on motorcycles probably immersed you in trying to squeeze every drop of horsepower out of an engine possible.

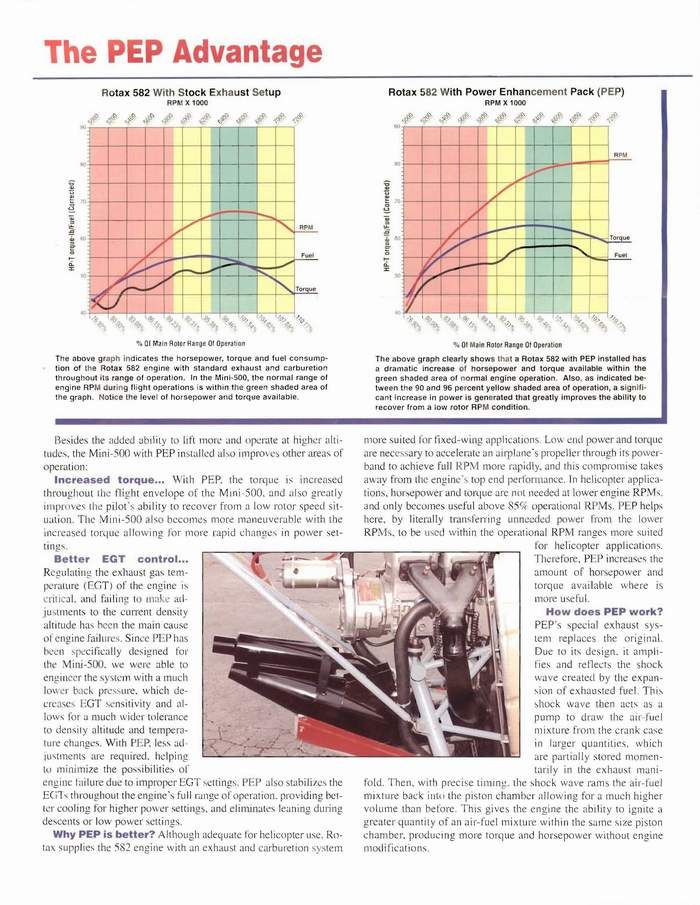

I guess I worded what I said wrong. When I said "takes the guesswork out," what I was trying to get across is, with access to a dyno, the results of all the trial-and-error work can be SEEN graphically on the plots, and all experimenting can be done on the ground.

Yes there will be a lot of trial and error but it is done safely ON THE GROUND and it can be tested to see if it reaches your goals without risking your life. I think most if not all dynos have very high quality EGT, CHT, Coolant, Fuel Flow, and Air Flow sensors which are way better that what is in most 2-stroke powered aircraft.

Unlike motorcycle racing, in aviation, getting the last ounce of horsepower out is probably not the goal when someone discusses putting a pipe on.

The goal may be one or some of these:

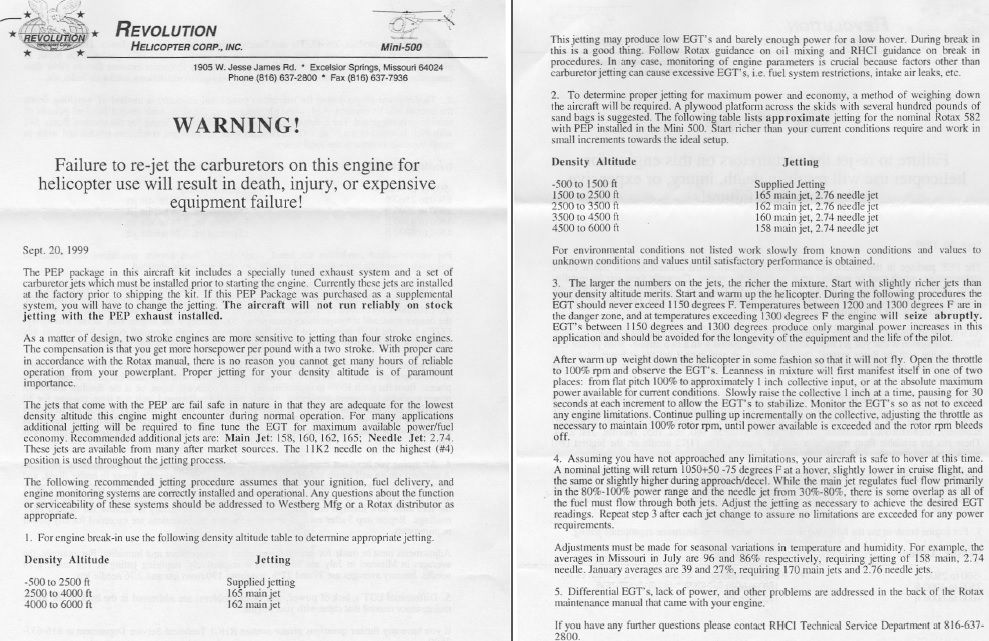

* Make the engine have more reserve power for use at higher density altitudes

* Make a helicopter engine have more reserve power for better low rotor RPM recovery

* Move the torque curve to better suit a propeller or airspeed range of a particular aircraft

* Change RPM/Diameter/Tip speed of the propeller to meet your needs I.E. faster cruise, better climb, noise abatement, clearance of parts of the aircraft structure.

Deciding your goal(s) of installing a pipe first, and then dyno-tuning the pipe by trial-and-error to make sure your specific goals are met is the only real way to get any benefit from a pipe.

The o.p. was asking about "dual" pipes. I would suspect that the benefits of each cylinder having its own pipe would be erased by the added weight. A single pipe, fabricated from thin aluminum, or even carbon fiber would go farther toward reaching your goals.

If the published plats are true, in the PEP literature I attached, Dennis' plots of the results shows his goals were met. He was trying to get a little more reserve power for hovering and low RPM recovery, and takeoffs over obstacles. He said he wanted to shift the torque curve of the 582, to better suit the Mini-500. He said he wanted fewer jetting changes to be needed with weather and density altitude changes.

All of my flying experience in the Mini-500 was pre-PEP pipe days so I have never flown with one. I look forward to having one on the ship I am building. There were a few very hot days in 1997 when I was hovering at full throttle and had to point my nose a little right of the wind and wait for a gust just to hop over a 4' fence and get into the pasture for a low performance takeoff. Then there were nice days where I was able to leave with a max-perf takeoff over the 40' telephone pole like in the video. A pipe would have been nice.