You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Reworking the Tail / HS & VS

- Thread starter Dirtydog

- Start date

treaze

Newbie

Dawg - For what it's worth, I used 0.016" for my tail--riveted, screwed, and epoxied. Two sheets. I got it from Aircraft Spruce. They rolled it and then wrapped corrugated cardboard around it, tucking the ends inside the roll. Unfortunately, when they did that, they bent the metal all the way around. So to be safe, order more than you need.

Dirtydog

Best seat in the house!

- Joined

- Oct 13, 2008

- Messages

- 2,298

- Location

- South, SC

- Aircraft

- Dogbee / Gyrobee

- Total Flight Time

- 18 duel/ 55 hrs in the Dogbee

Well after seeing all the tall tails at BD I have to say it is time to get busy and start cutting the stuff out to finish the tail. I was going to make it out of metal but wanted to try the epoxy resin first, I just love sanding as you know....

I have some of the pieces I have made using the lathe and milling machine already. Just a got to go on the foam. So tonight I am going to ge this done. Oh yea!

I finally got my new name for my bird since my N numbers are on. MISS GUIDED or MISS TAKEN tell me what you think! Both will have one of the sexy show girls to display!

I came up with name after talking to a CFI about my journey in becoming a pilot.

Thanks J.Grant for you help also!

I have some of the pieces I have made using the lathe and milling machine already. Just a got to go on the foam. So tonight I am going to ge this done. Oh yea!

I finally got my new name for my bird since my N numbers are on. MISS GUIDED or MISS TAKEN tell me what you think! Both will have one of the sexy show girls to display!

I came up with name after talking to a CFI about my journey in becoming a pilot.

Thanks J.Grant for you help also!

Last edited:

All_In

Gold Supporter

- Joined

- Apr 21, 2008

- Messages

- 16,105

- Location

- San Diego, CA. USA

- Aircraft

- Airgyro AG915 Centurian, Aviomania G1sb

- Total Flight Time

- Gyroplane 70Hrs, not sure over 10,000+ logged FW, 260+ ultralights, sailplane, hang-gliders

Hi DOG!!!

I like Miss Guided... it explains a great deal?

I like Miss Guided... it explains a great deal?

Resasi

Gold Supporter

- Joined

- Jul 2, 2007

- Messages

- 9,093

- Location

- London/ Kilifi Kenya

- Aircraft

- Gyrs, RAF 2000/Mgni/Bnsn/Hrnet/Mrlin/Crckt/MT-03/Lyzlle AV18-A/Prdtor. GT-VX1&2, Pax ArrowCopter

- Total Flight Time

- 100+ gyro, 16,000+ other

Aaah the origional Miss Fitt was certainly the babe, and gyro I thought was a real honey.

Chris you have to ask Mike where the model for his tail art lives, get her to get those shorty shorts a little higher, have a good transfer made, then be prepared to take a broom to all the drooling guys who'll stand around her.

Chris you have to ask Mike where the model for his tail art lives, get her to get those shorty shorts a little higher, have a good transfer made, then be prepared to take a broom to all the drooling guys who'll stand around her.

Timchick

Tim Chick

- Joined

- Sep 15, 2004

- Messages

- 10,894

- Location

- Panama City, Florida

- Aircraft

- Sport Copter Vortex, 582 Greyhead

- Total Flight Time

- ~30

I think Miss Fitt has a sister, Punkin'.

Dirtydog

Best seat in the house!

- Joined

- Oct 13, 2008

- Messages

- 2,298

- Location

- South, SC

- Aircraft

- Dogbee / Gyrobee

- Total Flight Time

- 18 duel/ 55 hrs in the Dogbee

Resasi & Timchick : What do you say for the name? MISS GUIDED or MISS TAKEN

Got my niece working on it now told here I wanted something sexy and she is makes laser cut out outs

Got my niece working on it now told here I wanted something sexy and she is makes laser cut out outs

Dirtydog

Best seat in the house!

- Joined

- Oct 13, 2008

- Messages

- 2,298

- Location

- South, SC

- Aircraft

- Dogbee / Gyrobee

- Total Flight Time

- 18 duel/ 55 hrs in the Dogbee

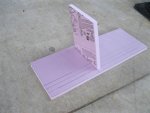

Tall Tail

Tall Tail

Log : MISS GUIDED is the name I am going to use!

Tall tail is cut out but i have to shape the leading edge. I am going to try this ER one more time. I am going to see about putting some kind of UV killer in it.

Epoxy Resin = ER

I cut the foam out to 22" x 60" for the main HS. I am still working on how big to make the VS

Tall Tail

Log : MISS GUIDED is the name I am going to use!

Tall tail is cut out but i have to shape the leading edge. I am going to try this ER one more time. I am going to see about putting some kind of UV killer in it.

Epoxy Resin = ER

I cut the foam out to 22" x 60" for the main HS. I am still working on how big to make the VS

Dirtydog

Best seat in the house!

- Joined

- Oct 13, 2008

- Messages

- 2,298

- Location

- South, SC

- Aircraft

- Dogbee / Gyrobee

- Total Flight Time

- 18 duel/ 55 hrs in the Dogbee

BUILDING LOG 4-4-2012 Tall Tail :

Started shaping the foam last night and I had forgot just why I dislike this part of building a tail so much. It is the little foam practical’s that seem to get everywhere, wearing a dust mask is needed when you use an electric sander to help shape the edges into place.

STEP - 1 : Before cutting anything off the square foam piece I marked the leading edge on the side and in the middle with a red magic marker to show the center of the leading edge which would have been 1” since the foam is 2” thick.

STEP - 2 : The place another line ½” on the same side you placed the red line. I use this line to help me get the taper started. This “RED” line in the middle should still be showing when the sand is finished. I used a razor knife to remove as much as possible before sand.

STEP - 3 : When you do use 80 grit sand paper on the sander helps shape the piece real fast. Remember you want to leading edge to be tapered also you want the air to flow around the taper freely.

STEP - 4 : After you have finished sanding the taper on the leading edge you are going to need to cut this piece off to install the 1” x 2” square 6061-6T that is 1.875 or 3/16” thick control spar since I have not seen any plans on this, so I am going to cut the leading edge or nose piece for the tail 3-1/2” wide as show in my drawings. Which will leaves the rear part to but 11-1/2” so my total width of the tail will be 15” long.

I am going to install some wooden dowels into the 3 pieces to help turn the all the pieces at the same time and also to strengthen the spar to the foam.

I am still working on my drawing to show my work.

Got to get ready for the fly inn this weekend.

Started shaping the foam last night and I had forgot just why I dislike this part of building a tail so much. It is the little foam practical’s that seem to get everywhere, wearing a dust mask is needed when you use an electric sander to help shape the edges into place.

STEP - 1 : Before cutting anything off the square foam piece I marked the leading edge on the side and in the middle with a red magic marker to show the center of the leading edge which would have been 1” since the foam is 2” thick.

STEP - 2 : The place another line ½” on the same side you placed the red line. I use this line to help me get the taper started. This “RED” line in the middle should still be showing when the sand is finished. I used a razor knife to remove as much as possible before sand.

STEP - 3 : When you do use 80 grit sand paper on the sander helps shape the piece real fast. Remember you want to leading edge to be tapered also you want the air to flow around the taper freely.

STEP - 4 : After you have finished sanding the taper on the leading edge you are going to need to cut this piece off to install the 1” x 2” square 6061-6T that is 1.875 or 3/16” thick control spar since I have not seen any plans on this, so I am going to cut the leading edge or nose piece for the tail 3-1/2” wide as show in my drawings. Which will leaves the rear part to but 11-1/2” so my total width of the tail will be 15” long.

I am going to install some wooden dowels into the 3 pieces to help turn the all the pieces at the same time and also to strengthen the spar to the foam.

I am still working on my drawing to show my work.

Got to get ready for the fly inn this weekend.

Attachments

Last edited:

Doug Riley

Platinum Member

- Joined

- Jan 11, 2004

- Messages

- 6,982

I use a hotwire rig to cut foam cores. Less dust. It does take some practice to get the heat and wire tension right, and to judge the progress of the saw through the foam.

Rutan's composite book tells you how to make your own hotwire saw from a car battery and wire, or you can cheat a bit and buy a plug-in power supply.

Remember that the leading edges must be ROUNDED, not tapered to a knife edge. The rounding radius should be about 2% of the airfoil's chord, e.g. a stab with a 24" chord would require a leading edge radius of 1/2".

Rutan's composite book tells you how to make your own hotwire saw from a car battery and wire, or you can cheat a bit and buy a plug-in power supply.

Remember that the leading edges must be ROUNDED, not tapered to a knife edge. The rounding radius should be about 2% of the airfoil's chord, e.g. a stab with a 24" chord would require a leading edge radius of 1/2".

choppergabor

Newbie

- Joined

- Apr 15, 2009

- Messages

- 4,864

- Location

- Sunshine State

- Aircraft

- N65GK Behemoth

- Total Flight Time

- Too few to mention

Agreed with Doug. Hot wiring is lot less messy. I was only surface repairing with the sander and made such a mess with that little bit of sanding! I used a 24 volt transformer and had a dimmer before if to adjust the juice. Simple little device can make the process much more accurate having the guides made ensuring the symmetrical and same size. A hint when you are done with your sanding. Affix a piece of wooden stick you can pick up at Michael's or any other craft store to ensure a nice straight even trailing edge. Much easier to glass over it that way  Good luck buddy. It is fun to make glass tail

Good luck buddy. It is fun to make glass tail

PS: come visit your brother and stop by me I'll give you mine with a $hitload of wire!!!!!!!!

PS: come visit your brother and stop by me I'll give you mine with a $hitload of wire!!!!!!!!

Last edited:

multimike

***** Supporter

- Joined

- Sep 19, 2009

- Messages

- 209

- Location

- Hooksett nh

- Aircraft

- Gyro-mz202-24 DW- N485MP

- Total Flight Time

- 100+

When I shaped the foam for my tail, I attached my shop vacuum to the random orbital sander which did a good job collecting the foam dust. The small amount of hand sanding showed me how messy it could have been.

Mike

Mike

Resasi

Gold Supporter

- Joined

- Jul 2, 2007

- Messages

- 9,093

- Location

- London/ Kilifi Kenya

- Aircraft

- Gyrs, RAF 2000/Mgni/Bnsn/Hrnet/Mrlin/Crckt/MT-03/Lyzlle AV18-A/Prdtor. GT-VX1&2, Pax ArrowCopter

- Total Flight Time

- 100+ gyro, 16,000+ other

Miss Guided sounds good Chris. Boy Mike really started something there.

Hope it goes well for your mods and you get your new tail back onto her, and yourself airborne again soon. Stu did say he was not happy about doing our tail and got help from Dan. Ours bubbled as well, but then dark blue probably not a great color for Florida.

Going back into hospital for another op the ankle, didn't manage to get across this year, and missed B days. The Hornet languishing in the back of the hanger, so not happy.

Did get in some very fun hours in on the Bensen during the surprise mini summer that hit the U.K. last month, but now back to grey skies, rain and snow, with temps in single figures.

The Air Force closed down civilian activities at Rissington recently, the FBO lost the lease. Hopefully though I will be flying from there in the new Military Autogyro Club that is starting up in the hanger we were in, a few of us, ex service, were invited to join.

The new club may also allow some of the other FW and gyro group who had to move out, back into the hanger to help offset costs, so with luck our old bunch will be up and flying together again soon.

Hope it goes well for your mods and you get your new tail back onto her, and yourself airborne again soon. Stu did say he was not happy about doing our tail and got help from Dan. Ours bubbled as well, but then dark blue probably not a great color for Florida.

Going back into hospital for another op the ankle, didn't manage to get across this year, and missed B days. The Hornet languishing in the back of the hanger, so not happy.

Did get in some very fun hours in on the Bensen during the surprise mini summer that hit the U.K. last month, but now back to grey skies, rain and snow, with temps in single figures.

The Air Force closed down civilian activities at Rissington recently, the FBO lost the lease. Hopefully though I will be flying from there in the new Military Autogyro Club that is starting up in the hanger we were in, a few of us, ex service, were invited to join.

The new club may also allow some of the other FW and gyro group who had to move out, back into the hanger to help offset costs, so with luck our old bunch will be up and flying together again soon.

choppergabor

Newbie

- Joined

- Apr 15, 2009

- Messages

- 4,864

- Location

- Sunshine State

- Aircraft

- N65GK Behemoth

- Total Flight Time

- Too few to mention

Oh I forgot to ask you what kind of epoxy you were going to use. My tail does NOT bubble anymore after the rightful age of over a year at least! (Jake told me the secret to it) So according to him (and proven being true!) if it's not vacuumed and just layed up like mine it will be sensitive even if the color is white! Less heat of course that way. But as you have seen the first Bensen Days debut did not spare mine either. I had 3 bubbles in less then an hour already when Jake pulled me over telling me to put her in the hangar right away. This year we had the sun blasting it for 4 days in the row on the flight line and no new bubbles. And she is dressed in pretty red too just like yours. Note the yellowish color of the epoxy. It is a high strength MARINE application epoxy. It is designed to take the sun and ultra violet. I hope this helps.

Attachments

Dirtydog

Best seat in the house!

- Joined

- Oct 13, 2008

- Messages

- 2,298

- Location

- South, SC

- Aircraft

- Dogbee / Gyrobee

- Total Flight Time

- 18 duel/ 55 hrs in the Dogbee

choppergabor : Well I still have buble problems even 2 years later. But I think I am going to use a pigment in the epoxy this time. At least on the wing parts. No one should have to deal with bubbles that long.

Resasi : The hospital thing is ruff, sister is going in for knee replacement. Hope all goes well keep you in a prayer! I still in the air right not not going to down her until I have it done and ready to transfer over the new TT

multimike : Yep my sand has the little dust bag on it... that help a lot!

Doug Riley : Not really hard to shape it with sand paper. Also I don't have a jig to help with the cut out!

I have not been able to work on the tail anymore side jobs have picked up with working on the golf carts for home owners after work and my Son Forrest kind of moved in, he brought his camper down and needed a place for about a month so I have been wiring the panel box for his hook up, ect...... his wife is expecting a baby in the next few weeks. Grand dad again. This is going to make 2 grand daughters. No boys yet!

1st grand daughter turn 2 next month on the 13th......oh boy!

Resasi : The hospital thing is ruff, sister is going in for knee replacement. Hope all goes well keep you in a prayer! I still in the air right not not going to down her until I have it done and ready to transfer over the new TT

multimike : Yep my sand has the little dust bag on it... that help a lot!

Doug Riley : Not really hard to shape it with sand paper. Also I don't have a jig to help with the cut out!

I have not been able to work on the tail anymore side jobs have picked up with working on the golf carts for home owners after work and my Son Forrest kind of moved in, he brought his camper down and needed a place for about a month so I have been wiring the panel box for his hook up, ect...... his wife is expecting a baby in the next few weeks. Grand dad again. This is going to make 2 grand daughters. No boys yet!

1st grand daughter turn 2 next month on the 13th......oh boy!

All_In

Gold Supporter

- Joined

- Apr 21, 2008

- Messages

- 16,105

- Location

- San Diego, CA. USA

- Aircraft

- Airgyro AG915 Centurian, Aviomania G1sb

- Total Flight Time

- Gyroplane 70Hrs, not sure over 10,000+ logged FW, 260+ ultralights, sailplane, hang-gliders

Congratulations Dog!

I've have 10 granddaughters and 4 grandsons and I enjoy all of them.

However only the boys will go to the airshows and on our last trip to Indiana. One the U-Haul trucks broke down. We were going to be stranded for two days. I offered to stay and they continue without me. They did not to do that, so I suggested that New Orleans is only about 5 or 6 hundred miles from here (in the wrong direction).

Why not take the cars we are towing and drive to New Orleans.

The girls loved it, being in a bar and listening to Dixieland bands.

The boys (5 & 7 yrs) were bored in about 15 minuets and wanted to run around.

So I took them outside to explore and as we turned the corner we saw to choppers all customized parked. The boys ran as fast as they could. They must have asked 1000 questions on what does that do?

Anyway we were there for over two hours when the girls came out they want to go to eat. But the boys wanted to stay and just look at the bikes.

They are all fun but they have different interests!

I've have 10 granddaughters and 4 grandsons and I enjoy all of them.

However only the boys will go to the airshows and on our last trip to Indiana. One the U-Haul trucks broke down. We were going to be stranded for two days. I offered to stay and they continue without me. They did not to do that, so I suggested that New Orleans is only about 5 or 6 hundred miles from here (in the wrong direction).

Why not take the cars we are towing and drive to New Orleans.

The girls loved it, being in a bar and listening to Dixieland bands.

The boys (5 & 7 yrs) were bored in about 15 minuets and wanted to run around.

So I took them outside to explore and as we turned the corner we saw to choppers all customized parked. The boys ran as fast as they could. They must have asked 1000 questions on what does that do?

Anyway we were there for over two hours when the girls came out they want to go to eat. But the boys wanted to stay and just look at the bikes.

They are all fun but they have different interests!

Tinman

Newbie

T Tail

T Tail

I built a T Tail for my gyrobee, lots of rudder athority and a hefty HS (58")

You can buy kit from http://www.starbeegyros.com/

http://webpages.charter.net/gadgetwizard/files/IMG_0021.JPG

http://webpages.charter.net/gadgetwizard/files/IMG_0024.JPG

http://webpages.charter.net/gadgetwizard/files/IMG_0025.JPG

T Tail

I built a T Tail for my gyrobee, lots of rudder athority and a hefty HS (58")

You can buy kit from http://www.starbeegyros.com/

http://webpages.charter.net/gadgetwizard/files/IMG_0021.JPG

http://webpages.charter.net/gadgetwizard/files/IMG_0024.JPG

http://webpages.charter.net/gadgetwizard/files/IMG_0025.JPG

Last edited:

Similar threads

- Replies

- 43

- Views

- 5K