bryancobb

Junior Member

- Joined

- Aug 2, 2010

- Messages

- 5,337

- Location

- Cartersville, GA

- Aircraft

- Owned Brantly B-2b/Fly Kitfox III/Mini-500b

- Total Flight Time

- 1350

Timing belts

Timing belts

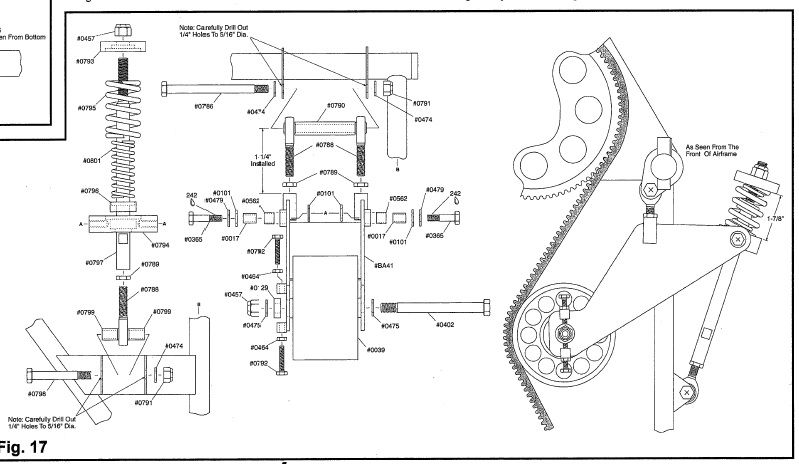

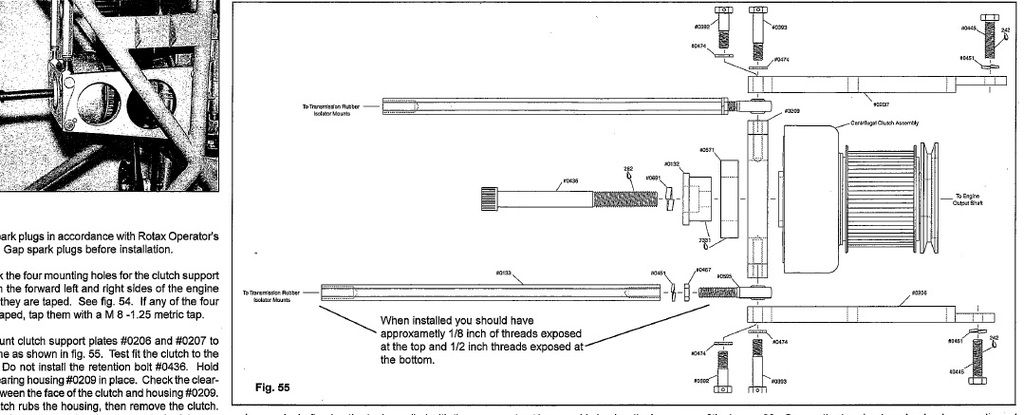

These types of belts are called `timing` belts because they, by design, cannot stretch or change length. It is not very old. It Line has 36 Kevlar strands in it and is stronger than steel.

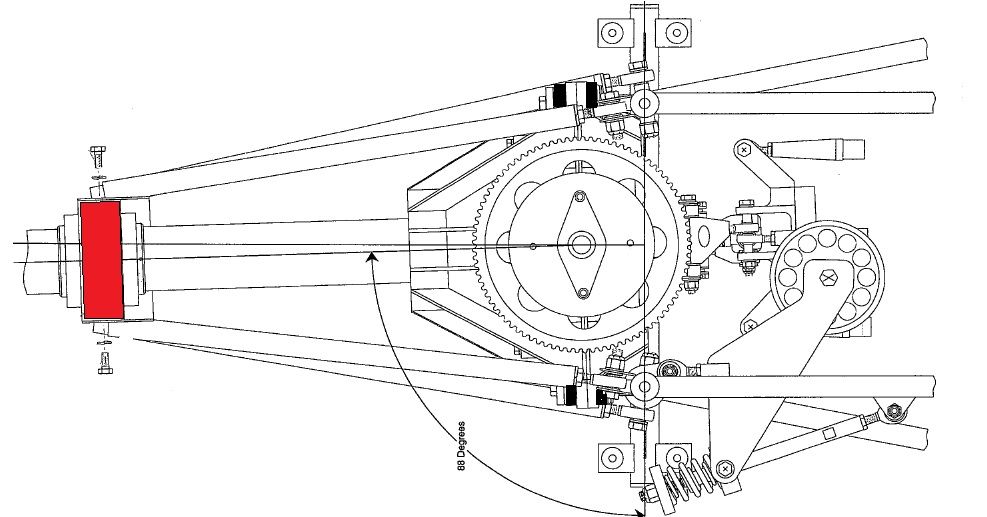

The idler pulley is spring-loaded and as the engine bounces up and creates slack, the idler/spring moves in to keep it tight.

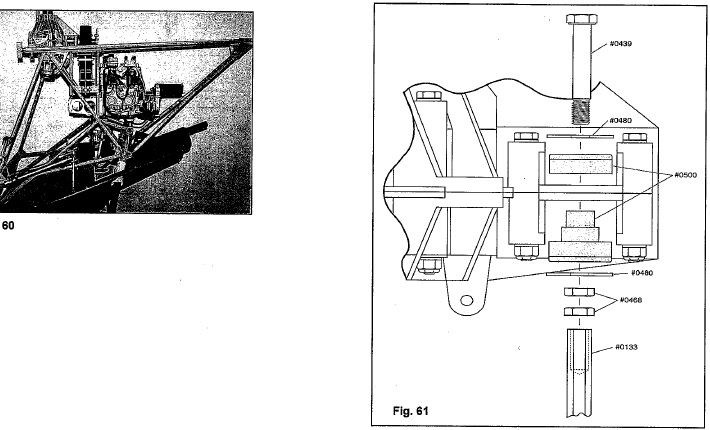

My current thinking is that the upper strut rubbers at the MRGB are just tooo softy! The hard ones are on their way!

Timing belts

Remember, this all does not start happening at all until I have hovered for several minutes

And this is the thing that SHOULD make it easier to isolate, coz it appears its temp related.

Just watchn your tensioner wheel, could the cog belt be stretchn under heat.

The tensioner looks to be gradualy pushed put ( as the belt climbs up the teeth) then drops back in ( as the teeth realine again, maken the circunferance smaller)

I know its a long shot, a f****n long shot.

These types of belts are called `timing` belts because they, by design, cannot stretch or change length. It is not very old. It Line has 36 Kevlar strands in it and is stronger than steel.

The idler pulley is spring-loaded and as the engine bounces up and creates slack, the idler/spring moves in to keep it tight.

My current thinking is that the upper strut rubbers at the MRGB are just tooo softy! The hard ones are on their way!

Last edited: