NoWingsAttached

Unobtainium Member

- Joined

- May 21, 2006

- Messages

- 4,871

- Location

- Columbia, SC

- Aircraft

- Air Command Tandem w/ Arrow 100hp; GyroBee w/ Hirth 65hp; Air Command Tandem w/ Yamaha 150hp

- Total Flight Time

- >350

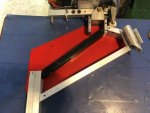

Moving the head mount forward on this a full 6" after swapping out the 320 lbs 130 HP Subaru for a 170 lbs 160 HP Yamaha, permanently leaving elephant Soobie mother-in-law on ground permanently...

Just finished up the Visio cheek plates redesign this evening, thought to share with you the old problems that jump out that need to be eliminated.

Anyone care to share thoughts for improvements on the obvious here? Hidden 1x2 rectangular tubing indicated in red lines. Yikes.

Just finished up the Visio cheek plates redesign this evening, thought to share with you the old problems that jump out that need to be eliminated.

Anyone care to share thoughts for improvements on the obvious here? Hidden 1x2 rectangular tubing indicated in red lines. Yikes.