Jens

GyroNew & Paraglider

- Joined

- Nov 5, 2004

- Messages

- 704

- Location

- Sønderborg - Denmark

- Aircraft

- Paraglider and PPG

- Total Flight Time

- Some hundreds

Correction...

Correction...

Correction to Post #71:

Most lift will come from prop not rotor

Moment has to be identical in top and bottom. Not necessarily hp.

Ratio between prop and rotor rpm should not go higher than 2:1, otherwise too many hps would go into the prop.

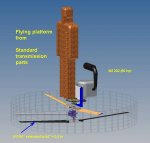

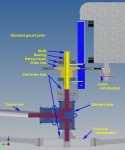

On picture below, rotor is now 14 ft and prop 72 in.

The figures might be something like this: (just a rough estimate)

700 rotor rpm x Moment = 20 hp

1400 prop rpm x Moment= 40 hp.

20 x 5,0 kg/hp = 100 kg lift = 220 lb.

40 x 2,5 kg/hp = 100 kg lift = 220 lb.

....................... 200 kg lift. = 440 lb.

Estimated overall lift per hp: 3,3 kg/hp = 7.3 lb/hp

I still hope the thing can be controled - can it?

Correction...

Correction to Post #71:

Most lift will come from prop not rotor

Moment has to be identical in top and bottom. Not necessarily hp.

Ratio between prop and rotor rpm should not go higher than 2:1, otherwise too many hps would go into the prop.

On picture below, rotor is now 14 ft and prop 72 in.

The figures might be something like this: (just a rough estimate)

700 rotor rpm x Moment = 20 hp

1400 prop rpm x Moment= 40 hp.

20 x 5,0 kg/hp = 100 kg lift = 220 lb.

40 x 2,5 kg/hp = 100 kg lift = 220 lb.

....................... 200 kg lift. = 440 lb.

Estimated overall lift per hp: 3,3 kg/hp = 7.3 lb/hp

I still hope the thing can be controled - can it?