StanFoster

Active Member

- Joined

- Nov 16, 2003

- Messages

- 17,139

- Location

- Paxton, Il

- Aircraft

- Helicycle N360SF

- Total Flight Time

- 1250

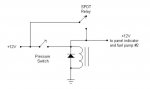

First of all...upfront I want to thank Heather Poe for sending me a wiring diagram for a circuit that automatically kicks a relay in to switch to the second fuel pump in the event the primary pump fails.

I took a break the other day and studied her diagram.....and then started realizing that I could easily adapt my fuel pumps to do the same thing.

If I have my main pump fail either by mechanical or electrical...or that one time back in May when I inadvertantly shut mine off....had I had this installed my second pump would have come on almost instantly.

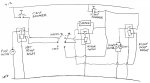

MY modified plan takes some of what Heather sent me and uses what I already have in my system.

One of these is a fuel pressure switch that comes on when my fuel pressure drops to a preset level. It operates an idiot light in my pod. However...that light is about worthless as when it comes on...the motor will be be dying within a second.

I am planning on having my fuel pressure switch also operate a relay that is installed in series with my second fuel pump. If the fuel pressure drops...this relay kicks in and runs the second pump. I will have it wired so that it will self excite itself and keep the relay on when the fuel pressure comes back on and switches the fuel pressure switch off. I am thinking I could have another light indicating that the second fuel pump is activated and that something has happened to the primary pump.

This relay would then be simply reset when I throw the switched breaker that is already wired to it. I could still test both pumps on preflight....by first starting on the main pump....switching its circuit breaker off...this would test the backup switching system and the second fuel pump. Then I would just switch the main pump back on...and shut the second pump off thus breaking the relay and resetting it for inflight use.

Note: I do have each individual pump on its own switched circuit and can alternate use between the pumps. I feel that if this works out...I will just let my main pump do all the work and have a fresh pump ready at all times to be instantly switched on when this relay is activated by low fuel pressure.

I think what Heather sent me and the way I want to modify it to simply adapt to what I have is a very simple system. I just need to research the right relay so that it switches the way I want....handles the amps...and can be self energized.

Any thoughts or modifications?

Stan

I took a break the other day and studied her diagram.....and then started realizing that I could easily adapt my fuel pumps to do the same thing.

If I have my main pump fail either by mechanical or electrical...or that one time back in May when I inadvertantly shut mine off....had I had this installed my second pump would have come on almost instantly.

MY modified plan takes some of what Heather sent me and uses what I already have in my system.

One of these is a fuel pressure switch that comes on when my fuel pressure drops to a preset level. It operates an idiot light in my pod. However...that light is about worthless as when it comes on...the motor will be be dying within a second.

I am planning on having my fuel pressure switch also operate a relay that is installed in series with my second fuel pump. If the fuel pressure drops...this relay kicks in and runs the second pump. I will have it wired so that it will self excite itself and keep the relay on when the fuel pressure comes back on and switches the fuel pressure switch off. I am thinking I could have another light indicating that the second fuel pump is activated and that something has happened to the primary pump.

This relay would then be simply reset when I throw the switched breaker that is already wired to it. I could still test both pumps on preflight....by first starting on the main pump....switching its circuit breaker off...this would test the backup switching system and the second fuel pump. Then I would just switch the main pump back on...and shut the second pump off thus breaking the relay and resetting it for inflight use.

Note: I do have each individual pump on its own switched circuit and can alternate use between the pumps. I feel that if this works out...I will just let my main pump do all the work and have a fresh pump ready at all times to be instantly switched on when this relay is activated by low fuel pressure.

I think what Heather sent me and the way I want to modify it to simply adapt to what I have is a very simple system. I just need to research the right relay so that it switches the way I want....handles the amps...and can be self energized.

Any thoughts or modifications?

Stan