mcbirdman

Gold Member

- Joined

- Oct 30, 2003

- Messages

- 1,242

- Location

- Grand Ledge (Lansing) Michigan

- Aircraft

- lw3 sp long, lw3 2place long yami

- Total Flight Time

- 150

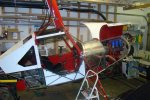

There have been two types of redrives for yamaha engine conversion on a Little Wing. Both are exciting as they both are dealing with finding the solution to finding an affordable, powerful and reliable powerplant. Not only for general home builts but more importantly one for the Little Wing.

Two choices have emerged, one is belt drive and one is using Todd's engine cage with geared reduction unit. I started this post for Tim Mercer as he has chosen geared reduction. Tim has been making GREAT PROGRESS ! Here is the latest email as sent to me:

James,

I have not been in touch for a long while! Hope all is well! I see you are making progress with the 2 place and the Yamaha engine layout! It would not be any fun if it were easy! RIGHT! LOL!

I wanted to post some pictures on the forum and show my progress but with computer issues I get locked up and the computer shuts down while trying to post so I gave up. Here is where I am at on my Little Wing today.

I had to work out how to get the cowl over the top of the engine without remaking the instrument panel, boot cowl and firewall. I added 2.25” to the top of the nose bowl I bought from Aircraft Spruce after I had raised it with a bent form and that was not enough so I fiber glassed an add on and then made a reverse scoop of aluminum to cover the water fill cap but still allow the gull wing doors to hinge from the firewall to the nose. It worked out well and looks kind of like a super cub now. I still have a few things to work out before I dismantle it for the umpteenth time and start covering and finish work. You may share these with the others as you desire and if you want and can you are welcome to post them on the forum under your “booster progress” post.

Take Care

Tim Mercer

Way to go Tim, I am excited for you and I appreciate you showing your progress. These photos will help me as I just got my engine from Todd.

jtm

Two choices have emerged, one is belt drive and one is using Todd's engine cage with geared reduction unit. I started this post for Tim Mercer as he has chosen geared reduction. Tim has been making GREAT PROGRESS ! Here is the latest email as sent to me:

James,

I have not been in touch for a long while! Hope all is well! I see you are making progress with the 2 place and the Yamaha engine layout! It would not be any fun if it were easy! RIGHT! LOL!

I wanted to post some pictures on the forum and show my progress but with computer issues I get locked up and the computer shuts down while trying to post so I gave up. Here is where I am at on my Little Wing today.

I had to work out how to get the cowl over the top of the engine without remaking the instrument panel, boot cowl and firewall. I added 2.25” to the top of the nose bowl I bought from Aircraft Spruce after I had raised it with a bent form and that was not enough so I fiber glassed an add on and then made a reverse scoop of aluminum to cover the water fill cap but still allow the gull wing doors to hinge from the firewall to the nose. It worked out well and looks kind of like a super cub now. I still have a few things to work out before I dismantle it for the umpteenth time and start covering and finish work. You may share these with the others as you desire and if you want and can you are welcome to post them on the forum under your “booster progress” post.

Take Care

Tim Mercer

Way to go Tim, I am excited for you and I appreciate you showing your progress. These photos will help me as I just got my engine from Todd.

jtm

Attachments

Last edited: